Standard Springs

- Jan 23rd. 2016

- By mapw

First outing of 2016 at Snetterton on Saturday 20th February. Should be a good day and a great selection of local Vauxhalls will be out on track.

An intermittent fault is somewhat tricky to diagnose and identify the cause until it becomes a permanent fault! So an intermittent non start was going to be entertaining to find as it could be electrical or fuel related. Additionally until rectified it meant trackdays had to be put on hold for obvious reasons.

After three weeks or so of using the car daily and having the non-start occur a couple of times, it eventually became a permanent non-start. Finally that gave me something to look for. Eliminating the crank sensor (they are occasionally prone to failure), as a crank signal was still present during cranking, it turned out that there was no fuel at the rail, and the fuel pump was not working.

Checked and tried a second known working fuel pump relay, not that. Removed the housing to check the pump in the tank; with the pump out of the tank, 12v from a second battery and the pump ran fine. So the pump was ok, which was good news as I have never seen a failure of an aeromotive 340 fuel pump to date. Next check all the fuel pump wiring in the housing, all ok.

Initially bridging/bypassing the fuel pump relay in the UEC (Underhood Electrical Centre) and the pump would run, so next check through the car loom from the UEC to the pump and the wiring all checked out ok for continuity. Also checked the 4 pin plug under the car next to the tank, in case it had suffered from corrosion.

So could it be the UEC? Fit another ‘slave’ test UEC, programme to the car, and fit the fuel pump relay and turn the key. Fuel pump primes and the car fires into life.

So problem solved, a fault within the UEC. Originally fitted with a UEC with Ident GR, a secondhand UEC from a 2010 car within the same Ident range (Ident LP) was sourced from a mate who runs a breakers for £50 which has since be fitted and programmed to the car and all is well.

Uunderhood Electrical Centre:

Vauxhall/Opel: UEC Part Number: 93184656 Ident GS Production Number: 13206746

Also Services Idents: GR GT GU GX GY GZ HA HB HC LM LN LP LQ LR

When sourcing a second hand unit ensure it has been correctly reset on Tech2 (or similar) for reprogramming.

Kind of does what it says on the tin! Made from a piece of 25mm wide x 4mm thick steel bar, zinc primed and finished with satin metal protect paint. A slightly stronger bracket to offer some additional support to the inlet manifold. It fits between the mounting point at the back of the manifold and the OE metal plate which is the mounting bracket for the vacuum store and is bolted to the lower rear of the block.

Trackday pictures from Snetterton on the 300 circuit. The day was organised by OpenTrack, with superb photographs by Tony Harrison.

Trackday cars are subjected to more extremes of use than road cars. The engine is subjected to more sustained hard use and the brakes, the tyres, wheel bearings and CV joints are also be worked harder with more heat generated.

Because of the harder use and higher temperatures experienced one area often overlooked are the CV joints. They will be subjected to higher temperatures, heat from the brakes especially will radiate into the CVs and driveshafts so a high quality CV grease is a good upgrade.

The CV joints in the car have already been stripped, cleaned and treated to new grease and boots and so will the spare shafts when they are cleaned and re-greased.

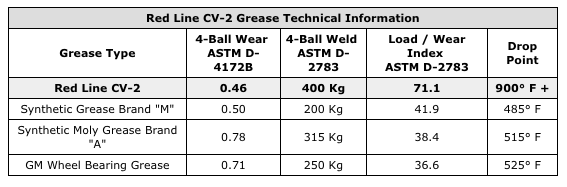

Redline CV-2 is my chosen grease.

CV2 Grease

Red Line Synthetic CV-2 Grease is formulated to withstand the extreme pressures and high temperatures found in racing and other high-performance wheel bearings and CV joints. The red moly compound and synthetic formulation give it a much higher load carrying capacity than black moly disulfide greases. Its excellent low-temperature flow, high-temperature stability, and very high drop point (melting point) of 900° F + (480° C+) allow it to be used at temperatures ranging from -100° F to 500° F (-70° C to 260° C), compared to a commercially available off the shelf CV Grease which has a sphere of operation between -10°C and 120°C CV2 is far superior.

It is highly resistant to oxidation and corrosion, and it has minimal effect on rubber seals. Automotive applications include wheel bearings, CV joints, U-joints, and general chassis lubrication.

CV2 Technical Info

Time for another engine oil change before the next track outing in April. I am switching over to Amsoil 5w-40 European Car Formula (AFL) Fully Synthetic oil.

Maximum Engine Protection

AMSOIL European Car Formula contains high-quality anti-wear additives and surpasses the tough ACEA oil specifications for high-temperature/high-shear viscosity. It provides outstanding protection in high-rpm, hot-running engines and delivers dependable long-term performance for the extended drain intervals set by European automakers.

Manufacturer Approvals:

Recommended For:

Full Spec (Click on Image to open PDF):

Well it would appear that the electrical gremlins have reappeared; the moment the car pulled out of the pit garage at Snetterton at the last track day!

With previous checks on the other electrical units carried out, the next logical place to look had to be the instrument pack, as this was still playing up. Vauxhall charge a retail price of £346 + VAT for a brand new instrument cluster. Having done yet more research it appears that a fault of some sort within the instrument cluster can cause the issues that have been experiencing.

Common faults with instrument clusters can manifest themselves as follows:

Now whilst I do not have all of the symptoms, certainly six of the above faults have been evident.

Removing the instrument cluster is pretty straight forward, once the upper and lower cowls are lifted clear the instrument cluster is held in place by 2 x T20 torx screws accessible at the bottom of the cluster; one each side. The cluster can then be removed from the bottom and once the multi plug is removed the cluster can be carefully lifted clear.

The cluster was then sent away for inspection and specialist repair. It was confirmed that there were a couple of issues with the circuit board(s), so these were repaired and the unit returned in a couple of weeks ready to fit, complete with a 2 year warranty on the repair work that had been carried out.

Fitting and programming the instruments (IPC) back into the car the expected result was ‘instrument panel functioning normally.’ Sadly this was not the case and the instrument needles dropped out as soon as the engine was started and the lights flickered!

So back to square one almost, and start again.

Thinking there was still an issue with the repaired instrument pack (IPC) the repaired cluster was then tried in another car; a car which had no other known issues. The repaired cluster functioned perfectly. So there was clearly no issue with the repaired IPC.

So another known working instrument cluster from another car was tried, but this played up as soon as it had been programmed and the car started. So the problem was clearly somewhere in the car.

The DTC’s remaining at this point were now just three:

U2100 IPC No Communication CANBUS Low Speed.

U2140 REC CANBUS No Communication with IPC

U2116 REC CANBUS No Communication with UEC

which was an improvement from when this first began as every conceivable DTC was present indicating lack of communication between everything electrical! UEC, REC, IPC, CIM…..

Looking at the DTC’s it suggested an issue in the REC.

Time to recheck the other electrical control units again……

Unplugged the stereo, just in case it was causing an issue. No change.

Try another known good headlight switch, because in the past the lights had been coming on randomly. No change.

A known good Rear Electrical Centre (REC) fitted and programmed. Still issues with the IPC.

A known good Underhood Electrical Centre (UEC) fitted and programmed. Still issues with the IPC.

The UEC that was tried had no fuses or relays in it, these had to be swapped across from the existing unit, so in case the issue was with one of these items another known working UEC was swapped across. All the pins and terminals were cleaned with electrical contact cleaner, and a coat of Ultra2040 water repellant (just in case) applied to the terminals in the wiring loom. Again no change, IPC still playing up.

REC multi plugs removed and cleaned with contact cleaner and refitted. No change.

So time to start checking earths……

Checked the 3 earth points next to the UEC. No change.

Removed the REC (again!), to gain access to an earth point behind the L/H/S quarter panel trim. The retaining nut unscrewed by hand….. so it was removed and the earth point and the retaining nut were cleaned with some 800 grit paper. The two earth wires were refitted and secured by the retaining nut.

Battery reconnected and engine started….. IPC functioning correctly.

So then it was just a case of swapping the REC back to the original one, the UEC back to the original one with the original fuses and relays and finally the IPC. After each individual unit was swapped back the car was started to check no issues had reappeared.

So chasing trouble codes turned out to be a slightly loose earth on the REC.

Note: Each time any electrical unit was removed the battery was disconnected prior to removal to prevent any current surges which could damage any electrics.

Blog detailing the build, modifications, updates, track days and more........